-

What We Do

We are creating an open source (freely available) model for insulin production that centers sustainable, small-scale manufacturing and open source alternatives to production. We are developing organisms and protocols to produce rapid acting (lispro) and long acting (glargine) insulin. Additionally, we are working on developing open hardware equivalents to proprietary production equipment, are researching sustainable regulation pathways to bring our insulin to the public, and are developing plans for local, small-scale manufacturing pilots.

-

Biotechnology Medicine Research + Development

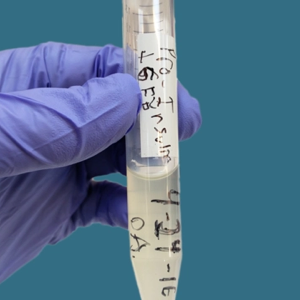

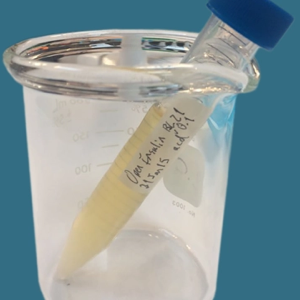

We are engineering microorganisms to produce long-acting (glargine) and short-acting (lispro) insulin analogs using standard techniques in biotechnology. We work with both bacteria and yeast. Our work is based on academic publications and off-patent processes. Our volunteers run experiments at our community labs in the US: Counter Culture Labs in Oakland, CA; BioCurious in Sunnyvale, CA; and Baltimore Underground Science Space (BUGSS) in Baltimore, MD. To learn more about our work in the lab, watch a quick video featuring our scientists Max and Yann.

-

Open-source Hardware for Protein Production

To produce the protein needed for insulin, we need to grow microorganisms with a bioreactor and purify the protein from the culture with a protein purification system (FPLC). Proprietary examples of this equipment come at a very high initial cost and with high ongoing costs of support from the manufacturers. Our goal is to develop easy to manage, easy to repair, and affordable equipment to sustain local and community-built insulin production.

Our FPLC design is in the early stages, and we are steadily developing mechanical and electrical designs to detect UV-C absorbance and manage the concentration of two buffers via peristaltic pumps and a mixing chamber. We plan to use Arduino microcontrollers as well as the Raspberry Pi, and the finished device will make use of the open-source Ender 3 3D Printer to facilitate automated fraction collection with G-CODE input. The bioreactor design makes use of quite a few commercial off-the-shelf parts and is ready for prototyping.

Open hardware equipment could be used for research and pedagogic purposes in addition to small scale manufacturing and we are looking forward to contributing it to the biohacking community in general.

-

Exploring Regulation Pathways

We are investigating regulatory pathways at the federal, state, and local levels. Under the U.S. Food and Drug Administration (FDA), our products (glargine, long-acting insulin, and lispro, short-acting insulin) will qualify as biosimilar (generic biologics) with the 351(k) BLA (biosimilar) pathway. We are exploring the possibility of reducing the costs of regulatory compliance without compromising safety by confining production to the state or local level. To learn more about the possibilities for bringing our insulin to the public, read: The Open Insulin Project: A Case Study for ‘Biohacked’ Medicines (2018).

We are looking to expand our network of experts and advisors who have a foundation in regulation pathways. Connect with us!